September 11th, 2018

It is important, above everything else, that a fire pump system have these two features:

A) no matter what, a fire pump must leak, or drip from the packing within the pump to keep it lubricated, and;

B) once a fire pump starts it must be stopped manually – that is someone must go to the pump and push the “red stop button.”

As a side bar, John Callaghan of Callaghan Pump and Controls notes that on a basic three month average a fire pump’s drain lines will clog. This is normal and usually occurs from paint scaling within the fire booster pump, from cast iron bits that become dislodged into the drain line, or from minerals or other deposits in the water. These types of clogs are normal; nonetheless, the fire booster pump must drip/leak, the frequency for which drips or leaks occur is up to pump owner, but the fire pump’s glands – bolts – should never be tightened so that it does not drip, since this is the only way a pump stays lubricated. Tightening the glands will score the shaft sleeve, and although it can be replaced, it could run you $6,000 -8,000 USD to replace your pump’s bronze shaft sleeve.

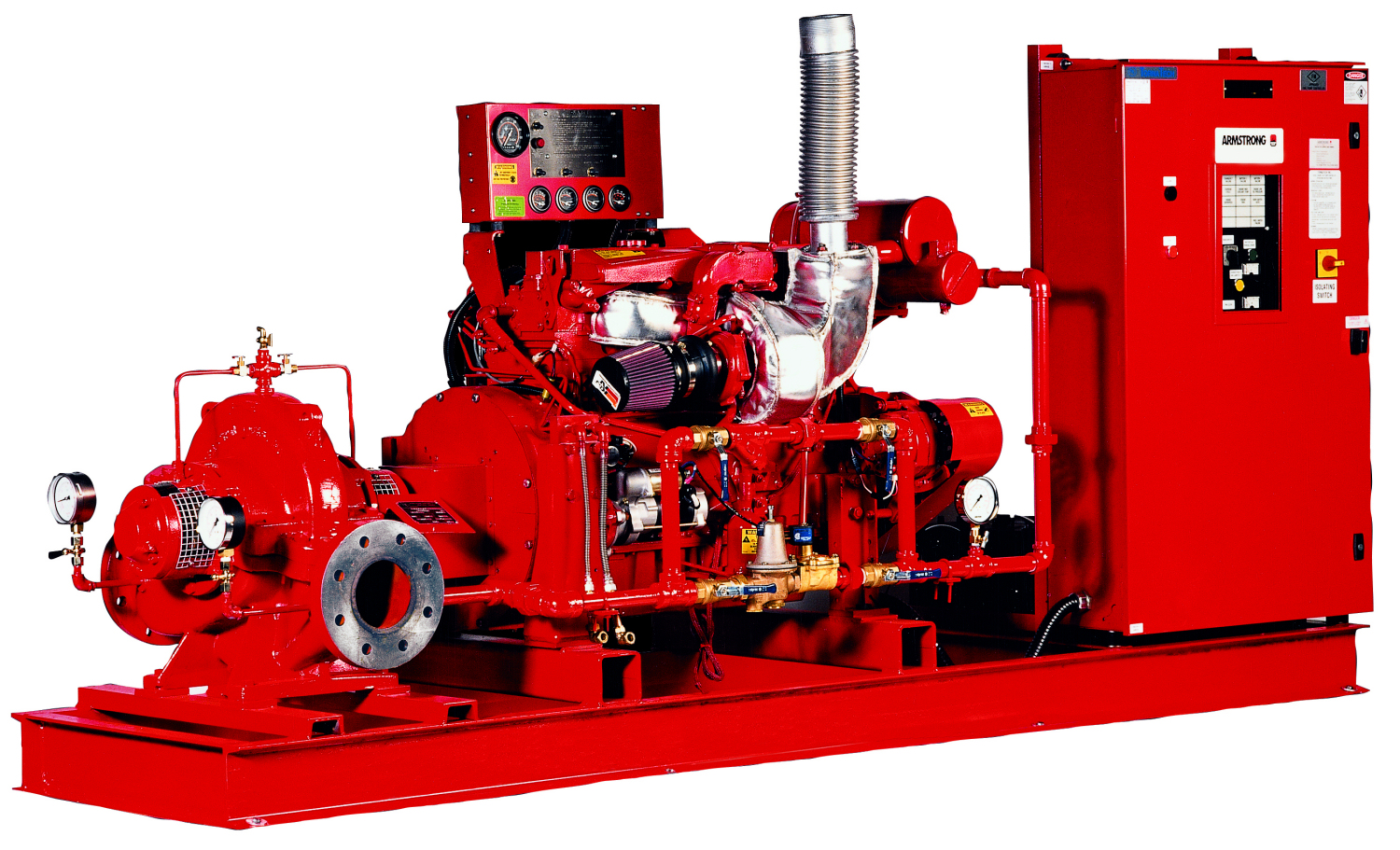

Aurora fire pumps, like every standard fire booster pump today, are built with packing inside. Remember, all fire pumps have water in them, packing keeps the water from splashing around and reaching the control panels. Aurora Fire Pumps, by Pentair, use the same assembling process as everyone else: they are packed and drip, and they must be stopped manually.

Callaghan suggests using Tornatech Control Panels with the Aurora fire pump system, they’re reliable, user friendly, and trusted in the pump industry. Older pumps may have different configurations, but the Aurora series has been updated to meet new standards within the last 10 years.

john@callaghanpump.com,

eileen@callaghanpump.com,

dan@callaghanpump.com,

sales@callaghanpump.com,

service@callaghanpump.com