September 26th, 2018

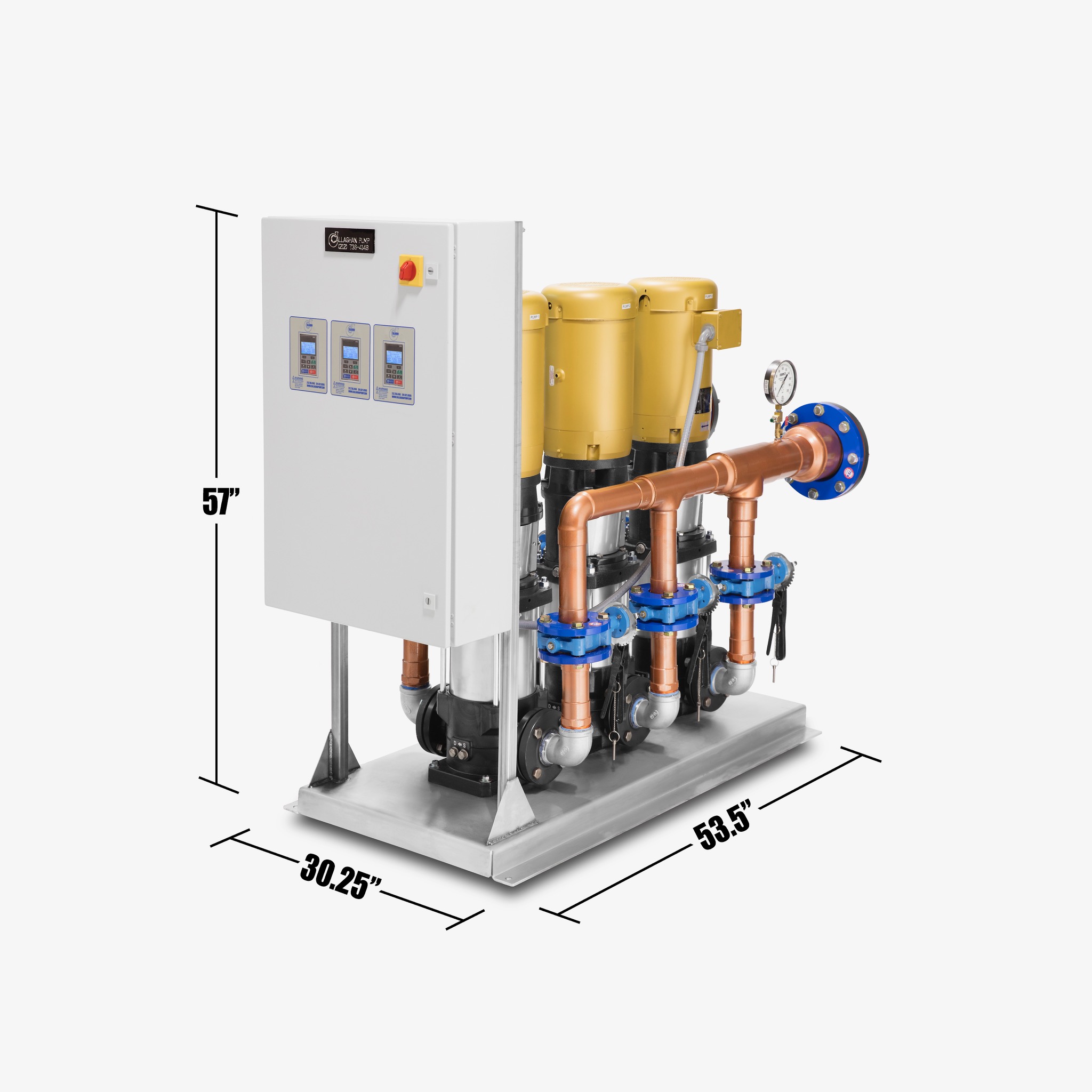

If you are thinking about installing a variable speed domestic water pumping system or tank fill system in New York City, or any other city you must first consider the core parts. The base should be stainless steel. Steel bases rust out in a matter of years and then the pumps are no longer stable. Take a look at the base: does it have holes to be filled with grout? This would be the best choice. Some people take stainless steel bar stock and make a base out of it, but this is nowhere near as sturdy as a solid plate, quarter-inch stainless which is all Callaghan pump uses for all of our variable speed pump systems.

Secondly, the header. Most plumbers love working with copper; all of our headers are copper and stamped with “NSF”, which means no lead. If they ever have an issue where they want to add something, any plumber can work with copper. While stainless steel looks nice, it’s very difficult to work with and most plumbers do not have the capability.

Next would be pumps. You can use cast-iron pumps, stainless steel pumps, or any other type so long as it does not have lead. If you’re dealing with low flow and high head, multistage pumps work very well. If it’s something where it’s 100 gallons a minute and 100 feet of head, you might want to stick with a single stage pump and suction style because of the fewer impellers and fewer moving parts.

Lastly, the controller. Always insist on a smart drive. no matter who makes it. Smart drive means you’re not going to require a PLC, or in other words, a third-party brain. Someone needs to program PLC‘s, and people’s experience and skill working with them vary. When you buy a smart drive from a company like Yaskawa, you’re dealing with thousands of people in engineering and 20 to 30 people in technical support. There’s a lot of knowledge and a lot of back up support programs that they write in these drives today that will be serviceable in 15 years, even 20 years. Most rotating equipment last 50 to 80,000 hours. If you’ve gotten that long out of it you certainly have done very well, but the key (again): the fewer parts you have the better off you’ll be.

Callaghan Pump’s systems have: stainless steel base, copper headers, the pump of your choice so long as it’s lead free, a control panel with a through the door, interlocked handle disconnect switch, two circuit breakers (one per drive), two Yaskawa variable speed drives, and two transducers. If one transducer were to fail, it sends an alarm and starts reading the second transducer. Everything is a complete independent redundancy. You can lose one drive, one pump, one circuit breaker and the other will work completely independently of the other. you do not have to rely on a flip-flop relay or any other logic to make it switch.

john@callaghanpump.com,

eileen@callaghanpump.com,

dan@callaghanpump.com,

sales@callaghanpump.com,

service@callaghanpump.com