August 22nd, 2018

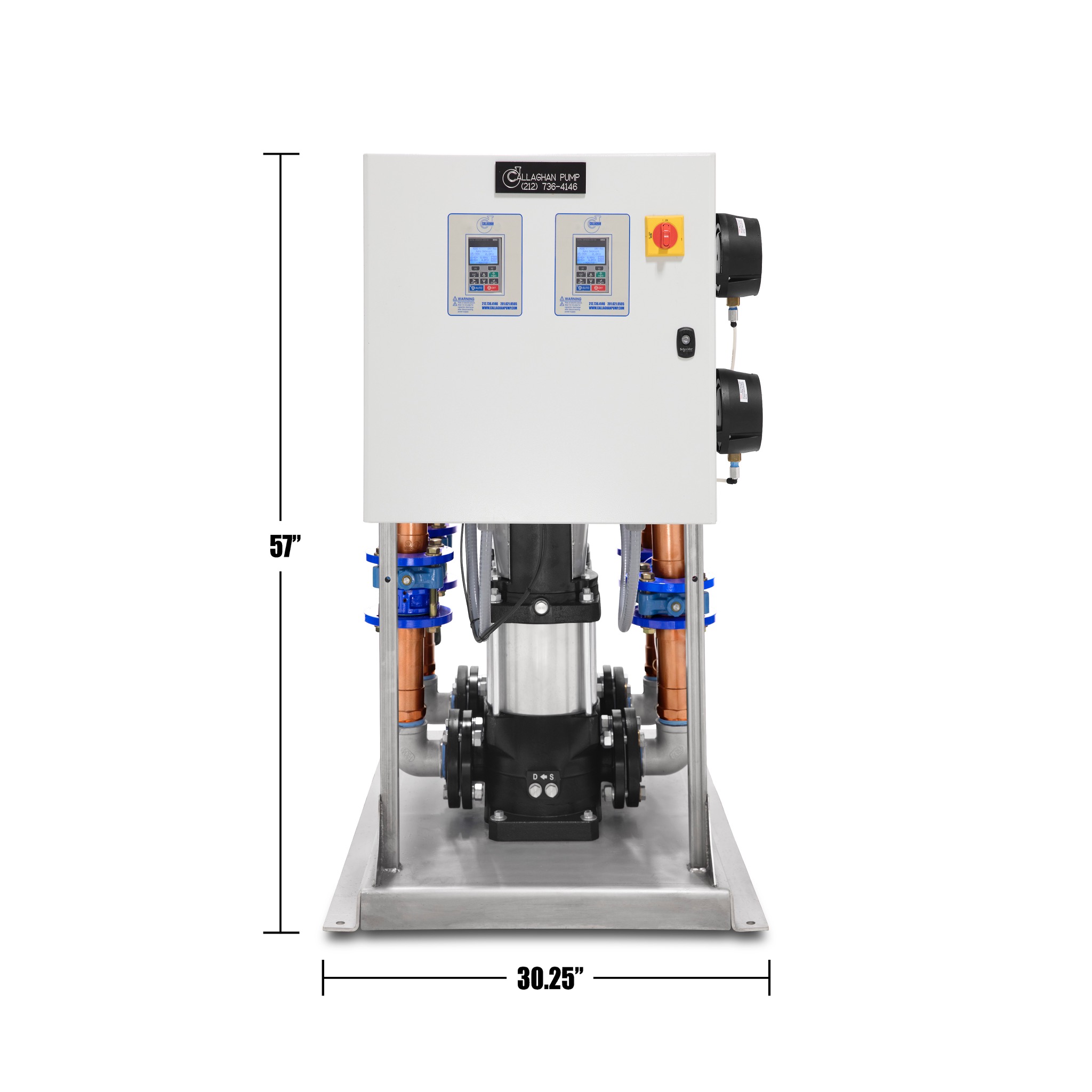

Callaghan Pump manufactures the highest quality and longest lasting pump system known on the market today. We use two very simple methods to make sure our systems last longer than any others. First and foremost is that our constant pressure/variable speed booster systems have as few parts as possible. They only feature what is needed to perform the task of boosting pressure in any type of building (low-rise, high-rise, a warehouse, etc.). If you want a constant pressure domestic water booster system we can build it.

We keep the system extremely simple by excluding extraneous items that fail early. The two most common items that we see failing are touch screens and programmable logic controllers. We don’t use either. We use the keypads that come with the drive. These keypads will have replacements available from the manufacturer for many years. We do not believe any other constant pressure booster manufacturers can say that about their touch screens. They are constantly updating touchscreens and removing old stock. I’ve spoken many times about the problems related to programmable controllers, and the second a smart drive was invented, I started using them instead. I never looked back to a PLC. A PLC requires that somebody sits down at a computer and writes a program that is very specific for a constant pressure booster system. The programmer may be good at his/her job, but many need to learn a few things and they learn them through trial and error. When you buy a smart drive, all those lessons have been learned 20 years ago. We don’t have programming errors anymore when we use a smart drive. One might accidentally put a decimal in the wrong spot, but this error does not require someone to come to the site with a laptop and a special cable and plug in to repair it. That is something you can fix right on the keypad with the full support of up to twenty customer service representatives at Yaskawa’s 1-800 hotline.

The number two reason our constant pressure/variable speed booster systems have very low failure rates is that we keep the inside of the control panel as cool as possible. We do this by cutting a hole in the back of our control panel for every drive. There is a kit that comes with the drive to make sure it stays watertight. This way, all the heat is drawn off of the drive with a heat sink and a large fan right on top of the heat sink. We put that device outside the control panel and then cover it with a powder-coated louver, specially designed for our domestic water pump systems. Every system gets this which makes our enclosure and control panel extremely durable, reliable and simple.

john@callaghanpump.com,

eileen@callaghanpump.com,

dan@callaghanpump.com,

sales@callaghanpump.com,

service@callaghanpump.com